We can support commercialization of your idea, please do not hesitate to contact us!

About Spiber

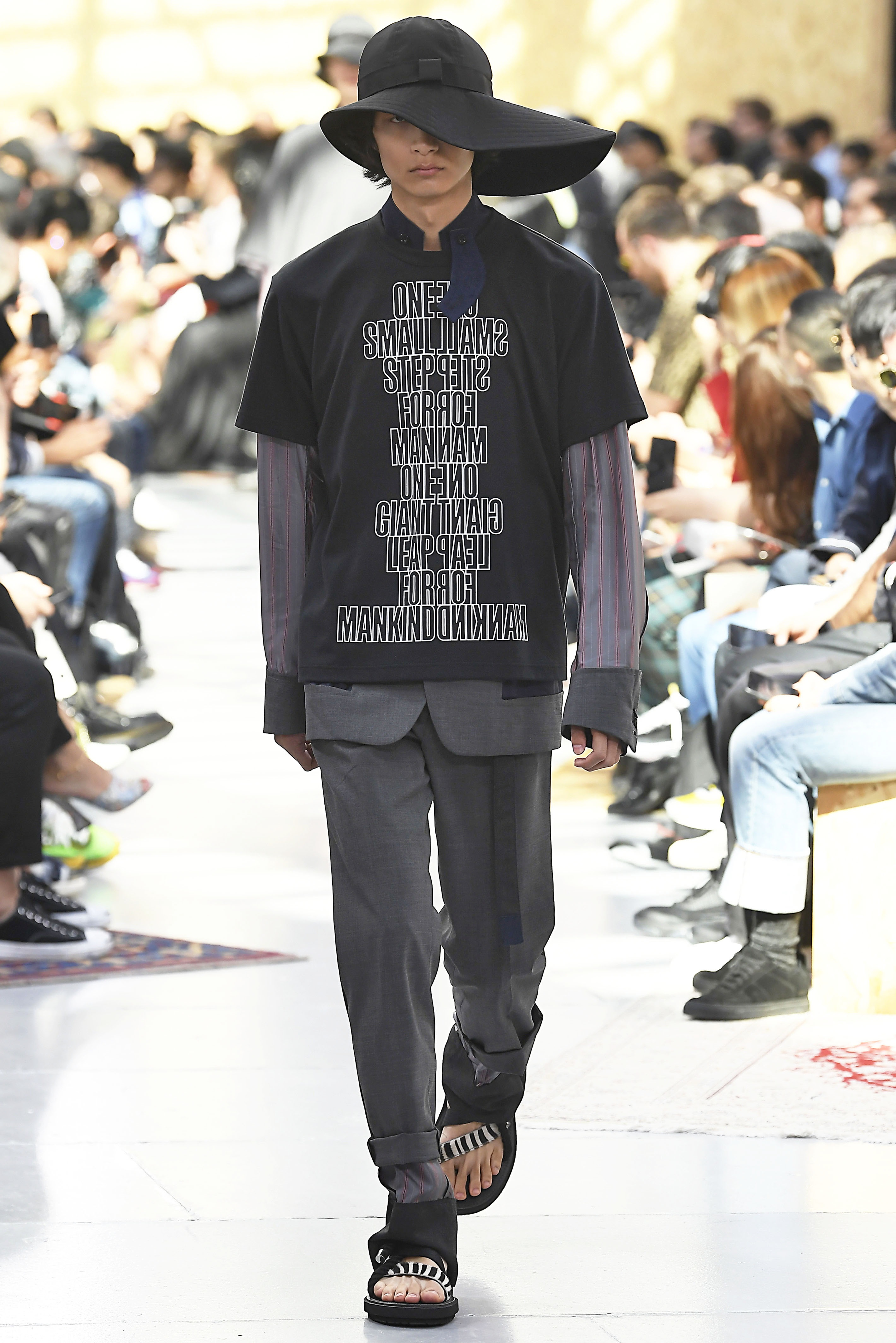

Established in September 2007, Spiber Inc. is a Japanese biotechnology startup utilizing cutting-edge synthetic biology, polymer, and material science for the development of novel protein materials known as Brewed Protein™. Produced through microbial fermentation and utilizing agricultural feedstocks as their primary raw material, Brewed Protein™ polymers are well-positioned to make significant contributions to animal-free and plastic-free initiatives in a range of fields, such as the apparel and automotive industries.

Brewed Protein™

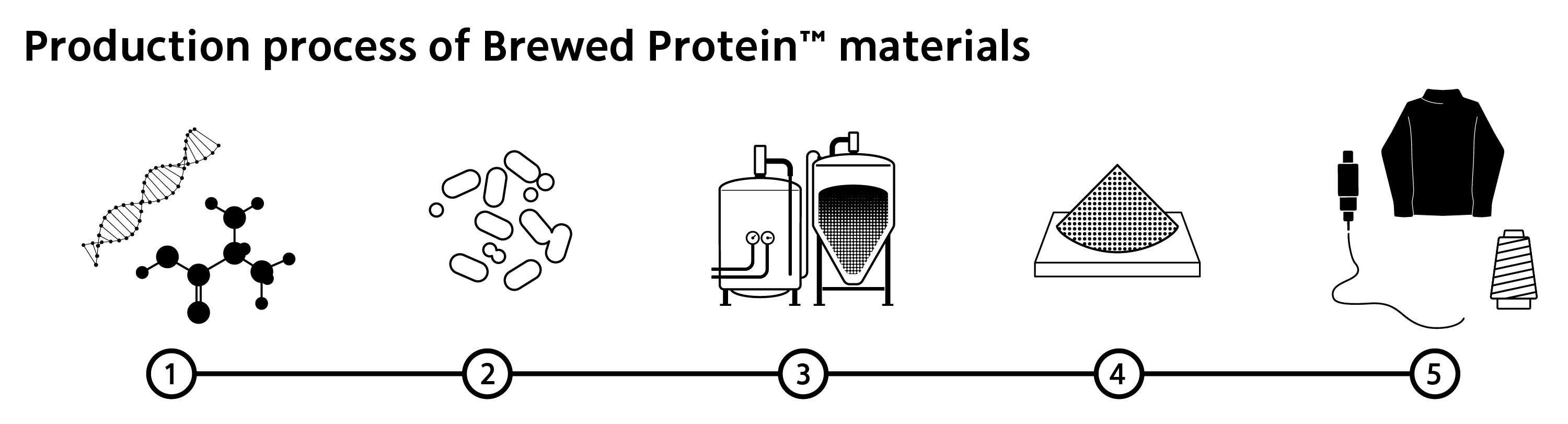

Brewed Protein™ materials are the protein fibers, films, and other types of materials manufactured using Spiber's proprietary fermentation (brewing) process. Through an evolutionary and iterative optimization process which begins at the molecular level, Brewed Protein™ materials can be tailored to suit the needs of specific applications in a range of fields and industries.

- ① Design and synthesize the genes that code for the desired amino acid sequence for our Brewed Protein™ polymer.

- ② Introduce these genes into microorganisms which are engineered to produce our proteins in a highly productive manner.

- ③ Ferment microorganisms in large-scale tanks using sugars to produce proteins.

- ④ Separate proteins from microorganisms and dry them into powder.

- ⑤ Process protein powder into a variety of forms, such as fibers, films, resin, etc.

KISCO specializes in the commercialization of advanced materials that will build an improved future. We are currently working with Spiber Inc. to realize the practical potential of next-generation, mass-produced Brewed Protein™️ materials.

- Business

-

- Synthetic resin

- Chemicals, food, biotechnology

- Electronics

- Packaging materials

- diX Coatings

Synthetic resin

Synthetic resin Chemicals, food, biotechnology

Chemicals, food, biotechnology Electronics

Electronics Packaging materials

Packaging materials diX Coatings

diX Coatings